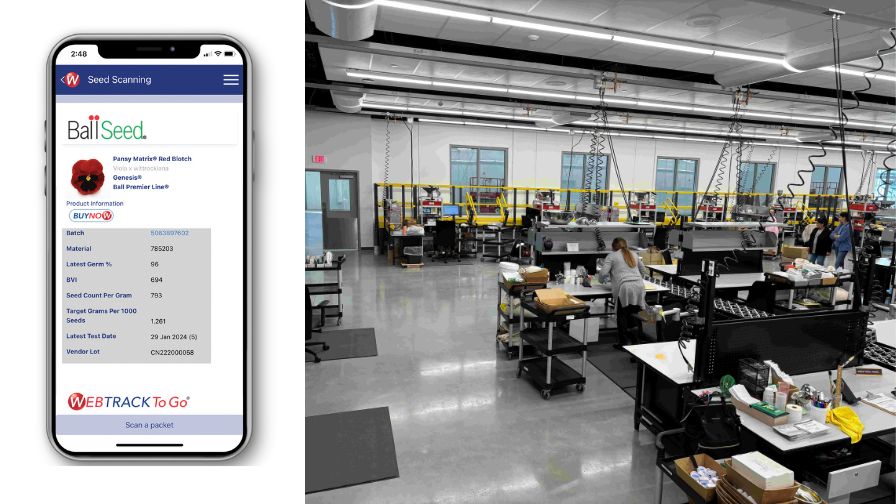

New product packaging labels through QR code (L) and West Chicago operations building (R) | Ball Seed

The seed packaging team of Ball Seed, a North American horticultural distributor, has successfully moved its operations into new, updated spaces in West Chicago, IL. Over a single weekend, the packing department was completely shifted to a recently built addition that will house the company’s Seed Distribution and Seed Processing systems.

This milestone coincides with the recent redesign of Ball Seed’s product packaging to improve functionality and efficiency for greenhouse growers. The packets have evolved from a 1D barcode to a new and interactive 2D QR code that, when scanned easily with a smartphone or scanning device, takes customers to real-time information and resources. This technology enhances customer access to timely seed-quality information, technical support, and marketing resources, putting all seed data in the palm of growers’ hands.

Some of the LIVE data shared by scanning the new labels include:

- Current Ball Vigor Index (BVI): the industry standard for measuring seed vigor and uniformity of germination.

- Current germination rate and most recent test date for the seed lot.

- Hyperlink to marketing support and technical information for germination and finishing.

- Material number, vendor lot number, and product description.

“Customer access to seed information has never been easier,” says Jim Kennedy, Senior Commercial Director of Ball Seed. “High-quality seed is the foundation of a successful season. Growers can use the data found on our seed packets to optimize their sowing and germination space.”

Seed offered by Ball Seed is tested to meet the company’s rigorous standards for professional growers. Seed is ready to ship the same day the order is received. If an order is received by 5 p.m., it will be out the door by 7 p.m. and Ball Seed can expedite to next-day delivery upon request. The increased access to seed data supports growers in making data-driven decisions in their production planning, allows predictable performance of seed during the growing season, and allows for more accurate production decisions.

“With the new seed label and efficient new space, Ball Seed is elevating our customer’s seed experience,” says Dave Hannebuth Ball Seed’s Seed Processing Center Manager. “All finished packaging – every seed coming off this line – now has the latest germ and real-time information growers can use to make informed decisions in their business.”

To support growers of all sizes, the Ball Seed label support team is ready to answer any questions and help link business systems to scanning devices. Please contact them at [email protected] and include a contact number to be connected by phone.